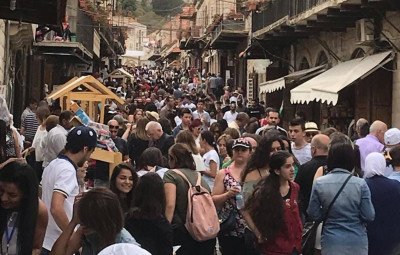

Grape Molasse Festival (Dibs al-anab) in Rachaya

Dibs al-anab is an ancient food made with reduced grape must that can be mixed with tahina and served with Arabic bread. It is thought to be one of the first sweeteners before cane sugar and honey were introduced in the Middle East and Mediterranean regions.It is usually used as a sweetener and as part of desserts alongside carob syrup and bee honey. It was used in the past as a substitute for sugar in lebanese villages and was also added to meat stew.It adds distinctive grape flavors to some cookies and baked goods.

Dibs al-anab is an ancient food made with reduced grape must that can be mixed with tahina and served with Arabic bread. It is thought to be one of the first sweeteners before cane sugar and honey were introduced in the Middle East and Mediterranean regions.It is usually used as a sweetener and as part of desserts alongside carob syrup and bee honey. It was used in the past as a substitute for sugar in lebanese villages and was also added to meat stew.It adds distinctive grape flavors to some cookies and baked goods.

Besides its delicious taste, Dibs al-anab is well known for its different benefits such as: ability to give the skin freshness, softness and beauty; natural remedy for childhood constipation; blood sugar stabilizer; good source of calcium which may support bone health and reduce the risk of osteoporosis; rich in antioxidants which help protect against chronic diseases.

Besides its delicious taste, Dibs al-anab is well known for its different benefits such as: ability to give the skin freshness, softness and beauty; natural remedy for childhood constipation; blood sugar stabilizer; good source of calcium which may support bone health and reduce the risk of osteoporosis; rich in antioxidants which help protect against chronic diseases.

In Lebanon for centuries, Rashaya has been known for its successful artisanal grape growing industry. The production of Dibs al-anab passes through different stages. After the grapes are fully ripened, they are transformed into piles, and then pressed through a metal machine that runs on electrical energy, manufactured locally in Rashaya. The juice leaks through channels and openings into tanks made of “stainless” or zinc iron, instead of hollow tanks in the rock. Then the juice is left for eight hours, attached to white limestone soil known as “hawara” or “clay,” which is an essential material in this production because it extracts acidity from the grapes and helps purify and filter the juice, as the sediments are suspended in it to settle at the bottom of the tank, containing a calcareous substance. It is a sufficient period of time for the juice to become clear and free from sediment. Then the “jamjool” (what is known as the remnants of the extracted clusters) is collected, and it is stacked under a pressure machine, called the “piston”, instead of stacking it under the weights of the stone cylinders in order to withdraw the rest of the juice. After this process, the juice is transfered to the “Khalqin” made of copper, and it is boiled for a period ranging between one hour and one hour and 15 minutes, at a temperature ranging between 130 and 140 degrees. During the boiling process, the “turbidity” that floats on the surface of the “Khalqin” is removed using an oval-shaped boiler dotted with holes through which the clean liquid leaks. When the humidity reaches 20%, the density is 80%, then the molasses has matured and is ready to be transported to special refrigerators to be stored.

In Lebanon for centuries, Rashaya has been known for its successful artisanal grape growing industry. The production of Dibs al-anab passes through different stages. After the grapes are fully ripened, they are transformed into piles, and then pressed through a metal machine that runs on electrical energy, manufactured locally in Rashaya. The juice leaks through channels and openings into tanks made of “stainless” or zinc iron, instead of hollow tanks in the rock. Then the juice is left for eight hours, attached to white limestone soil known as “hawara” or “clay,” which is an essential material in this production because it extracts acidity from the grapes and helps purify and filter the juice, as the sediments are suspended in it to settle at the bottom of the tank, containing a calcareous substance. It is a sufficient period of time for the juice to become clear and free from sediment. Then the “jamjool” (what is known as the remnants of the extracted clusters) is collected, and it is stacked under a pressure machine, called the “piston”, instead of stacking it under the weights of the stone cylinders in order to withdraw the rest of the juice. After this process, the juice is transfered to the “Khalqin” made of copper, and it is boiled for a period ranging between one hour and one hour and 15 minutes, at a temperature ranging between 130 and 140 degrees. During the boiling process, the “turbidity” that floats on the surface of the “Khalqin” is removed using an oval-shaped boiler dotted with holes through which the clean liquid leaks. When the humidity reaches 20%, the density is 80%, then the molasses has matured and is ready to be transported to special refrigerators to be stored.

Ingredients: concentrated grape juice, sugar, water, citric acid, sulphite ammonia caramel

Nutrition: Every 100 grams of grape molasses contains 330 calories, 80.9 grams of carbohydrates, 0.4 grams of fat, 0.9 grams of protein, and minerals containing 74 milligrams of calcium (equivalent to approximately 7%), and 1.2 milligrams of calcium. iron, and 40 mg of phosphorus.